Die casting, Squeeze casting advantages

Die casting, Squeeze casting advantages

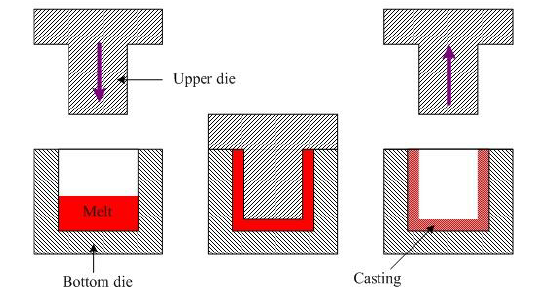

Die casting/Squeeze casting is a method of forming metal into shapes by using two dies that are squeezed together. Most casting techniques use two dies that are squeezed together before the metal is added but, in squeeze casting, the two are pushed together after the metal is added. This is done with liquid metal, and the upper die is only removed when the metal has cooled. By using this technique, the metal will typically come out stronger, with a better grain and less metallic shrinking. This commonly is done with magnesium, aluminum and their alloys, but many other metals can be used.

There are several advantages to squeeze casting that increase the metal’s functions. The first one is that the metal will typically be stronger, because the cooling method forms a better shape when compared to other casting techniques. There is a tight seal and pressure between the two dies, so less metal is able to evaporate, leading to less shrinking during the cooling process.