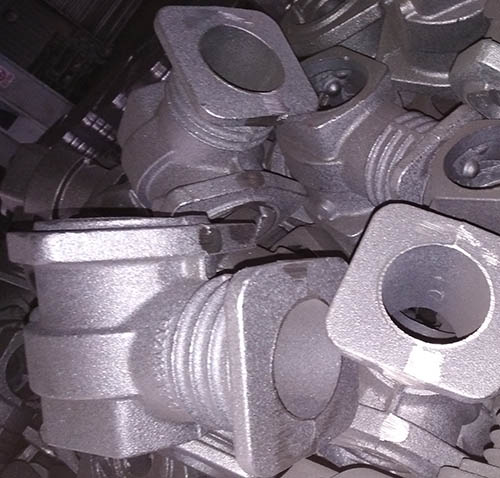

China foundry - Gray iron casting

Iron castings are generally manufactured by using a variety of melting methods, different types of castings are produced with varying properties.

The most common types of iron castings are grey iron (gray iron), ductile iron and malleable iron. Gray iron castings are typically made by smelting pig iron and they are an alloy of iron and carbon. Gray iron castings also possess traces of phosphorous, sulfur, silicon and manganese in them. The main reasons as to why gray iron castings are a popular choice are their cost efficiency and capability to be made into complex frameworks. Let's take a look at some of their basic characteristics, features and applications.

The most common types of iron castings are grey iron (gray iron), ductile iron and malleable iron. Gray iron castings are typically made by smelting pig iron and they are an alloy of iron and carbon. Gray iron castings also possess traces of phosphorous, sulfur, silicon and manganese in them. The main reasons as to why gray iron castings are a popular choice are their cost efficiency and capability to be made into complex frameworks. Let's take a look at some of their basic characteristics, features and applications.

- Gray iron castings are available in different tensile strengths from 5 tons per square inch up to even 19 tons per square inch. The average tensile strength is around 7 tons per square inch and it is possible to increase their strength easily, if needed for specific applications.

- Gray iron castings own the ability to withstand large amounts of compressive forces and thus have a high compressive strength, which is about three times more than its tensile strength. This is the foremost reason as to why they are a premier choice for huge posts and columns in big buildings.

- Gray iron castings have high damping capacity and excellent machining capabilities, which make them perfectly suitable for all types of machine bases, cylinder blocks as well as brake parts.

- Another important characteristic of gray iron castings is that they are highly resistant to oxidation, which in turn leads to prevention of rust. Gray iron castings are the ideal solution to overcome problems of corrosion.

- There are numerous uses for gray iron castings and they are usually classified into categories based on their class. Class 300 Gray Iron is mostly used in the production of beds, gears, cylinder blocks, heavy-duty machine tools, high-pressure hydraulic components, cylinder heads, bushings, piston rings etc. Class 200 and Class 250 are mostly suitable for manufacturing cylinder bases and liners, brake wheel, gearboxes, coupling plate, flywheel and pressure valves. Class 100 and Class 150 category are typically utilized for creating hammers, pipes, pulleys, protective covers, hand wheels, bearings and pumps. Gray iron castings are the optimal choice for the construction of highly durable and strong products.

All the above-mentioned characteristics and the applications make gray iron castings the most widely used type of cast iron.

China foundry -HR foundry is the best choice for parts from Gray iron casting.