Automatic molding castings cast iron parts

Automatic molding castings cast iron parts

HR foundry uses the automatic molding line to produce iron casting parts for vehicle parts, car parts, truck parts, agricultural parts, tractor parts, pump parts,valve parts etc. We owned 6 automatic production lines.

The advantages of automatic molding are high production rate, good dimensional tolerance, good surface quality, and very stable casting quality.

However, the disadvantages are high metal pattern cost, high MOQ, the limitation of size and unit weight of castings.

During molding, the electrical furnaces will start to melt the irons. The raw materials for ductile iron and grey iron include pig iron, scrap returns, and alloy agents.

The automatic molding line can perform the molding process automatically, only need one worker to operate the machine.

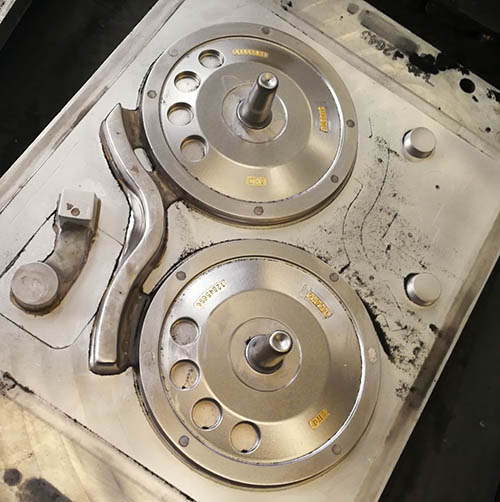

Iron patterns are the necessary tooling for automatic molding line, so the pattern cost is high comparatively. The metal patterns are made by CNC milling machine to gurantee the dimensional tolerance and surface quality are very good.