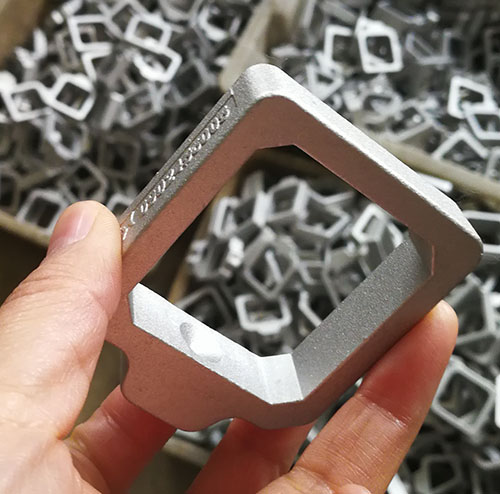

Advantages and disadvantages of investment casting

The investment casting is known as lost wax casting, mainly includes silica sol casting and water glass casting.

The advantages of investment casting listed as below:

<Excellent surface finish

<High dimensional accuracy

<Extremely complicated shaped parts are castable

<Almost any metal can be cast

<No flash or parting lines

The main disadvantage is the overall cost, especially for short-run productions. Some of the reasons for the high cost include specialized equipment, costly refractories and binders, many operations to make a mould, a lot of labor is needed and occasional minute defects. However, the cost is still less than producing the same part by machining from bar stock; for example, gun manufacturing has moved to investment casting to lower costs of producing pistols.

<This process is expensive, is usually limited to small casting, and presents some difficulties where cores are involved.

<Holes cannot be smaller than 1/16 in. (1.6 mm) and should be no deeper than about 1.5 times the diameter.

<Investment castings require longer production cycles compared to other casting processes.

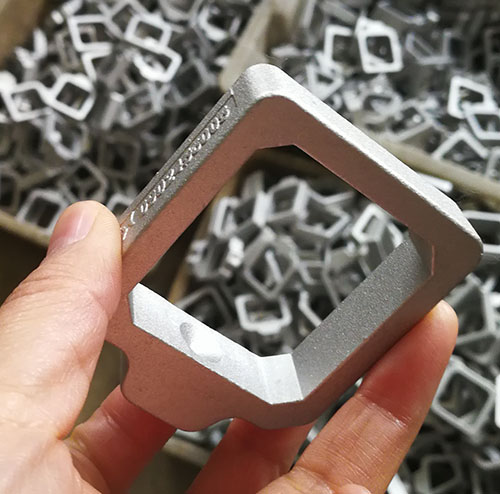

The advantages of investment casting listed as below:

<Excellent surface finish

<High dimensional accuracy

<Extremely complicated shaped parts are castable

<Almost any metal can be cast

<No flash or parting lines

The main disadvantage is the overall cost, especially for short-run productions. Some of the reasons for the high cost include specialized equipment, costly refractories and binders, many operations to make a mould, a lot of labor is needed and occasional minute defects. However, the cost is still less than producing the same part by machining from bar stock; for example, gun manufacturing has moved to investment casting to lower costs of producing pistols.

Additionally:

<It may be difficult to cast objects requiring cores.<This process is expensive, is usually limited to small casting, and presents some difficulties where cores are involved.

<Holes cannot be smaller than 1/16 in. (1.6 mm) and should be no deeper than about 1.5 times the diameter.

<Investment castings require longer production cycles compared to other casting processes.