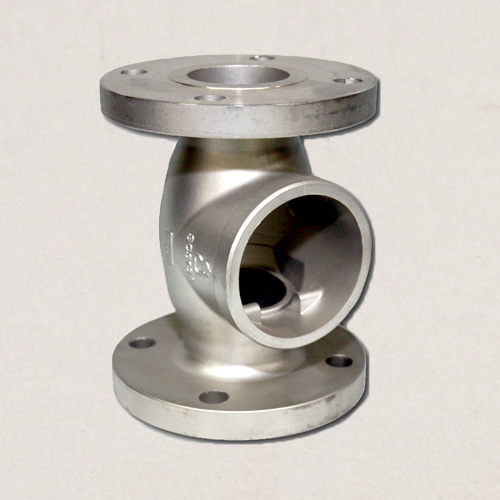

Low Pressure Casting Aluminium alloy Casting Parts

One of the major advantages of low pressure casting is the smaller gating system compared to gravity casting. Feeders are normally not necessary (head feeders only in the minority of cases) which reduces the cycle material. In low pressure casting, cycle material is 5 % to 20 % of casting weight whereas in gravity casting it can be up to 100 %. Less gating material also means that costs for cleaning, trimming and melting-down can be reduced significantly. Costs for cleaning are mainly personnel costs, especially for foundries with small quantities for which automated cleaning or press punching is not profitable at all. Considering increasing energy costs, which means USD / kg melting, each kilogram of unnecessary melting should be avoided.

Low pressure casting:

1: Material: Based on the standard of ASTM, GB, JIS and DIN, as per customers' request.

2. Surface treatment: polishing, shot blasting, chrome plating, power coated, anodizing etc.

low pressure casting, low pressure aluminium casting, aluminium casting, low pressure aluminium alloy casting, alloy casting, casting parts, low pressure aluminium casting parts

Experience

Low Pressure Casting Aluminium alloy Casting Parts

One of the major advantages of low pressure casting is the smaller gating system compared to gravity casting. Feeders are normally not necessary (head feeders only in the minority of cases) which reduces the cycle material. In low pressure casting, cycle material is 5 % to 20 % of casting weight whereas in gravity casting it can be up to 100 %. Less gating material also means that costs for cleaning, trimming and melting-down can be reduced significantly. Costs for cleaning are mainly personnel costs, especially for foundries with small quantities for which automated cleaning or press punching is not profitable at all. Considering increasing energy costs, which means USD / kg melting, each kilogram of unnecessary melting should be avoided.

Low pressure casting:

1: Material: Based on the standard of ASTM, GB, JIS and DIN, as per customers' request.

2. Surface treatment: polishing, shot blasting, chrome plating, power coated, anodizing etc.

low pressure casting, low pressure aluminium casting, aluminium casting, low pressure aluminium alloy casting, alloy casting, casting parts, low pressure aluminium casting parts